Introduction:

The project aimed to design a professional-grade printed circuit board (PCB) capable of efficiently controlling LED brightness, managing a 230V relay, and monitoring temperature and humidity.

Leveraging the ESP32-S3 chip, renowned for its versatility and robustness, the design process followed rigorous engineering standards to ensure safety, reliability, and optimal performance.

Power Management:

Safety was prioritized in the power supply design.

A meticulous approach was taken to step down the 230V AC mains power to a stable 12V DC with the help of the HLK-20M12, providing a safe and efficient voltage level for LED illumination.

Subsequently, a sophisticated buck converter was integrated to further regulate the power, generating 5V for sensor operation and 3.3V for the ESP32 microcontroller and associated buttons.

Control Interface:

The local user interface was carefully crafted to provide seamless control and operation.

Various buttons, including the SMD boot button for ESP32 download mode initiation, a reset button for system reset functionality, and a dedicated button for local activation of the 230V relay, were strategically placed for accessibility and ease of use.

Additionally, a high-quality potentiometer was incorporated to enable precise control over LED brightness, enhancing user experience and functionality.

Sensor Integration:

Central to the design was the incorporation of temperature and humidity sensors, pivotal for comprehensive environmental monitoring.

Carefully chosen for their precision and dependability, these sensors deliver real-time data, crucial for maintaining ideal environmental parameters.

Moreover, these sensors are meant to seamlessly integrate with Home Assistant via MQTT.

This integration will enable dynamic control over my climate system, allowing for precise adjustments to heating, cooling, and humidity levels based on real-time environmental data.

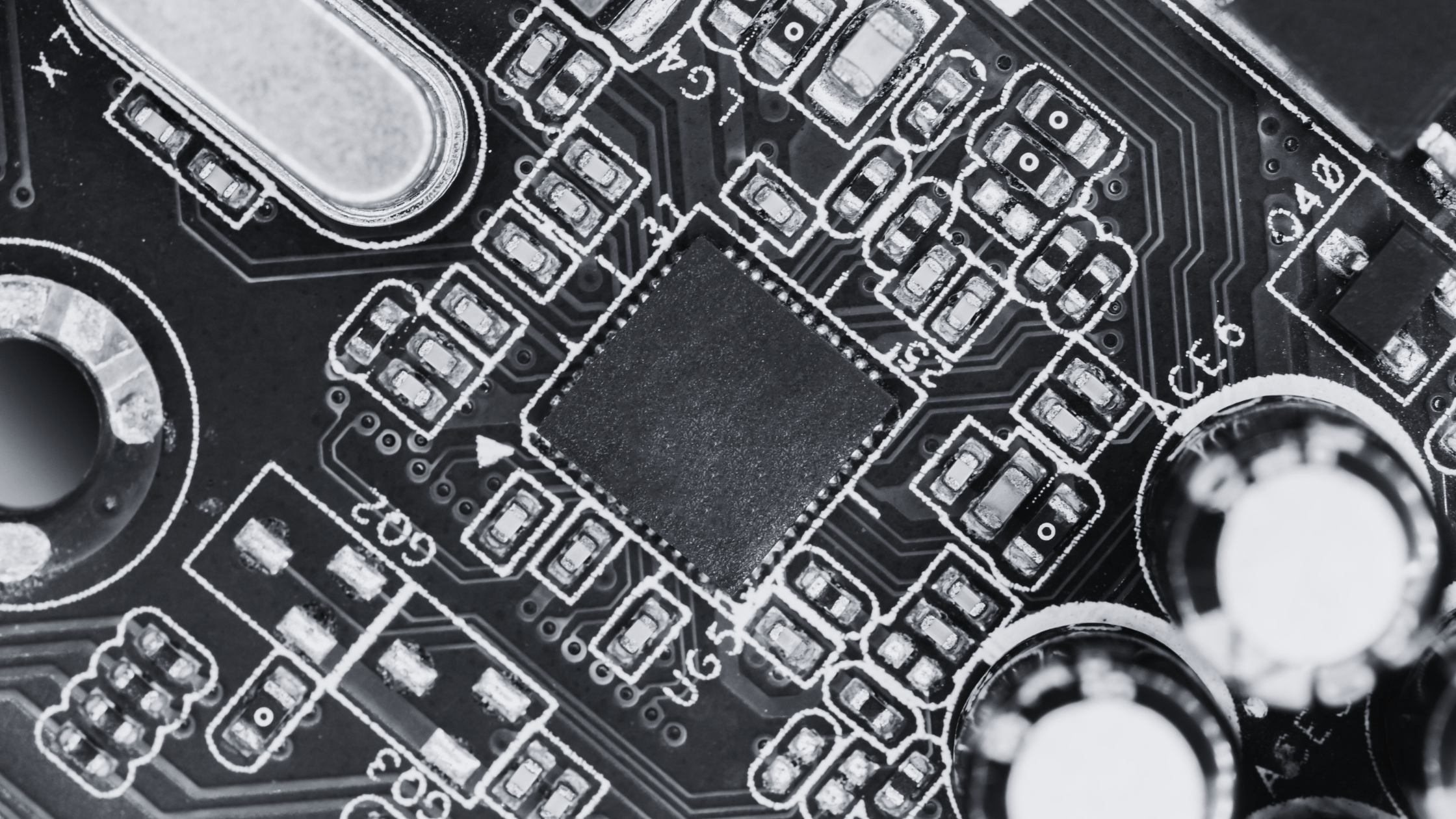

PCB Layout and Prototyping:

The PCB layout was meticulously designed to optimize signal integrity, minimize interference, and maximize space efficiency.

Through iterative prototyping and rigorous testing, potential design flaws were identified and addressed, resulting in a refined and robust final product.

The layout adheres to industry standards, ensuring compatibility with manufacturing processes and facilitating scalability for future iterations.

Conclusion:

The completed PCB design stands as a testament to my professionalism, innovation, and meticulous attention to detail.

By seamlessly integrating LED brightness control, 230V relay management, and environmental monitoring capabilities, it offers a comprehensive solution for a wide range of applications.

As a versatile platform built on the foundation of the ESP32-S3 chip, it represents the pinnacle of engineering excellence, poised to meet the challenges of today and tomorrow with unwavering precision and reliability in the IoT industry.

Check out the schematic and PCB design on my github.

- Date: April 2, 2024

- Categories: PCB Layout and Design

- Project Files GITHUB